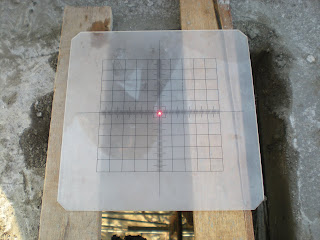

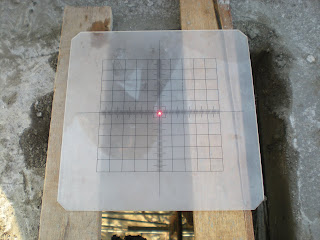

15-4-2010(Thurs)I met with my company surveyor, Mr Azizul in the morning. I found a surveying equipment that i never seen before. It is

laser plumb instrument.

The sharpness of the laser can be adjusted by the black knob.

Mr Azizul was adjusting the board with a big cross lines.

As u can see, the laser was at the centre of the cross lines.

Then, Mr Azizul set the total station by using the centre of the board as set point.

Activity of the day-

concrete casting to Level 3 slab & beam at c/c: E2-J/10a-14a

The concrete G35N(Grade 35) is flow into the concrete pump machine.

The machine is operated by an operator. He will control it to pump the concrete when the concretor order through walkie talkie from Level 3.

The concrete is pumped to Level 3 through these pipes.

The concrete is vibrated by this poker vibrator to let the air out and reduce voids.

The concretors are pulling the concrete to the empty space.

This worker is flattening and smoothening the concrete and makes sure the concrete is in the required level.

This equipment is called mechanical distributor. It make the concrete easier to distribute on large area, save time and save human energy also.

The slab after the concrete dried.

Slab

Scaffoldings are erected to prop the slabs and beams.

Side fomwork is sawn to the slabs and beams.

The steel pipes are laid to support the slabs.

Then, formwork is sawn to the slabs.

After that, the bar benders start to do the reinforcement work to the beams.

Next, reinforcement work is done on the slabs.

The electrical PVC pipe conduit c/w junction boxes are installed to the slabs.

Underfloor trunkings are also installed.

The slabs that are ready for concrete casting.

The machine is operated by an operator. He will control it to pump the concrete when the concretor order through walkie talkie from Level 3.

The machine is operated by an operator. He will control it to pump the concrete when the concretor order through walkie talkie from Level 3.

This worker is flattening and smoothening the concrete and makes sure the concrete is in the required level.

This worker is flattening and smoothening the concrete and makes sure the concrete is in the required level.

This equipment is called mechanical distributor. It make the concrete easier to distribute on large area, save time and save human energy also.

This equipment is called mechanical distributor. It make the concrete easier to distribute on large area, save time and save human energy also.

No comments:

Post a Comment